Bicycle |

Abstract | |

| Welcome to the next technical project's documentation by ZWZ! You will be introduced to the process of the making of an electric drive for a bicycle. This is no new discovery, but off-the-shelf bicycles are either of poor parameters, or too costly. The method stated herein will indeed let you save some money and get yourself a unique piece of hardware, but if you do decide to make this real, you will have to put much time in this and stir the bottom of your handyman heart. |

Components | |

|

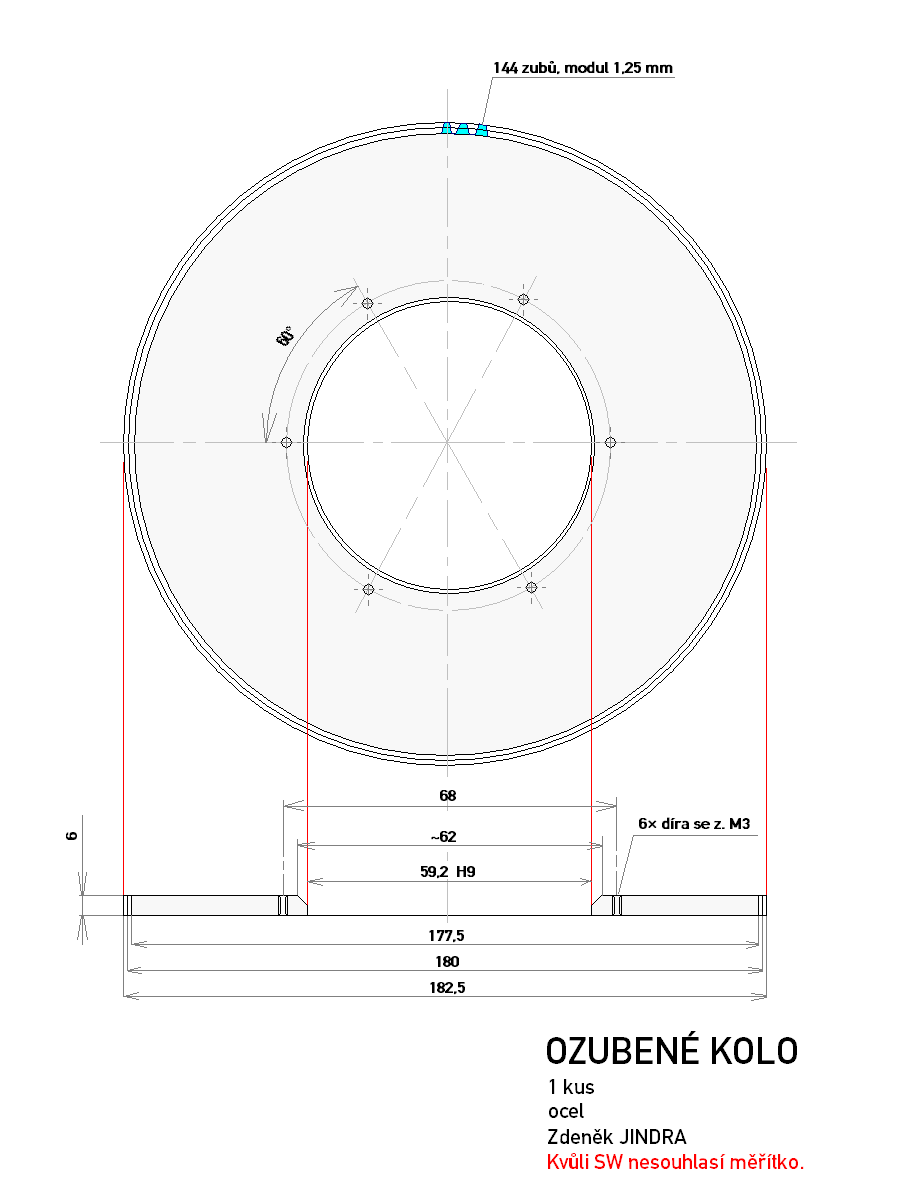

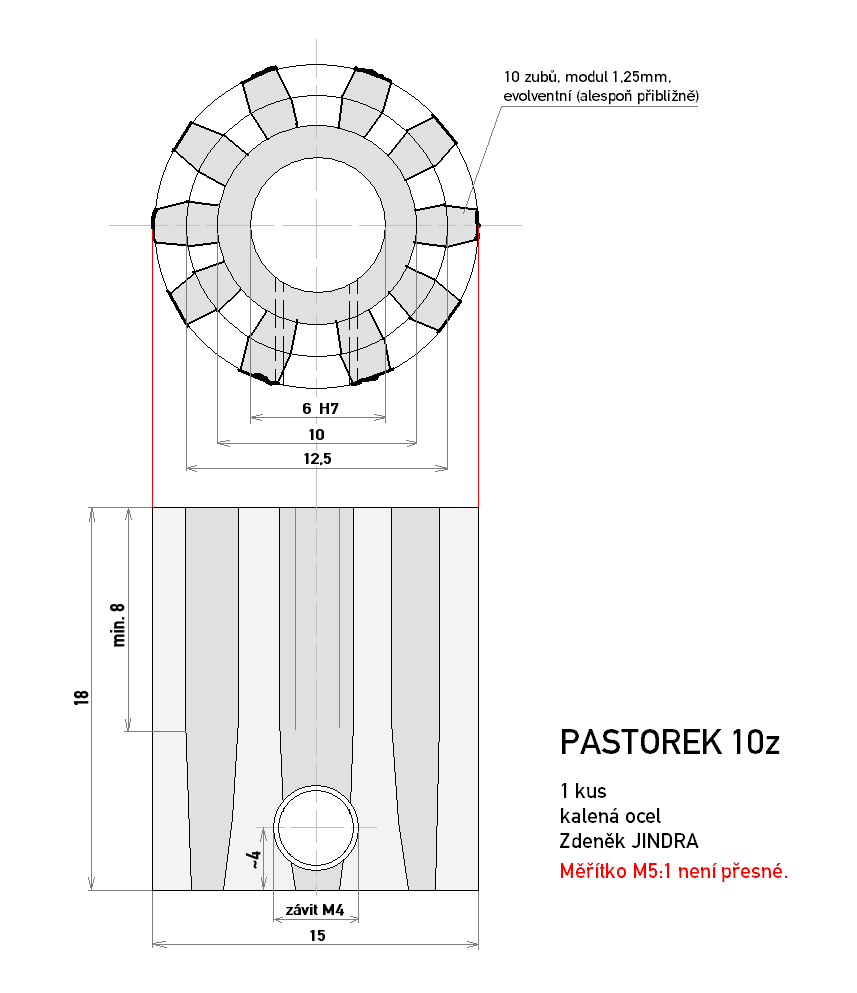

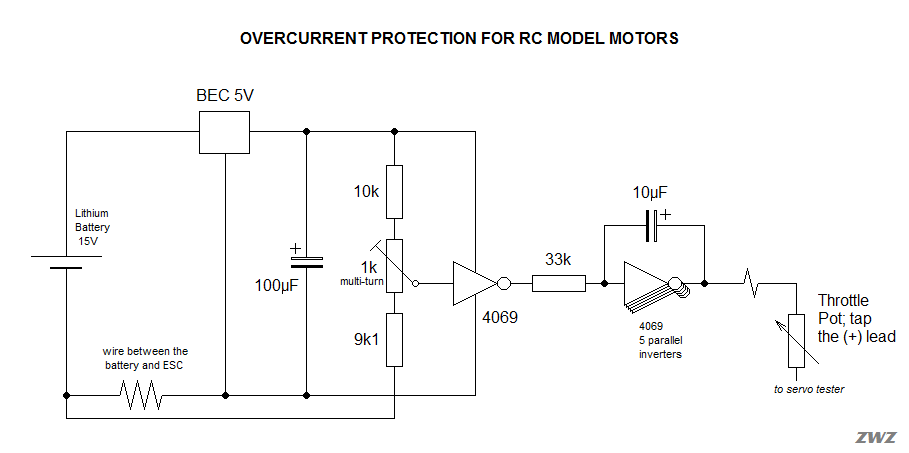

Please check this list of the required properties of your bike prior to any purchase so that it is compatible with the project. It is best to already buy a bike with these in mind. • Men's frame with triangular shape. This excludes most frames with rear wheel suspension. If you insist on a non-triangular frame, you will need a rear bracket with a carrying case. Otherwise get a regular triangular frame. • Rim brakes. The gear mounting method used here is incompatible with disc brakes. • Suspended front fork. These have a more regular and comprehensible cylindrical shape so that you can make the needed clamps easier. Furthermore it is simpler to evaluate the free space needed for the gears or pulleys since the buffers run parallel. In case of fixed iron fork, you may attempt to weld the motor mounting to it directly. (Not tested!) • Cutout on the insides of the buffer cylinders for the freewheel and gear wheel. I.e. Suntour NEX 4000. • The same count of wires for which a rear threaded hub can be purchased. You will need to weave a new rear hub into your front rim. Buy one with the same number of holes (mine had 36). It is needed to replace the axis of this hub first so that it fits in the front fork and hopefully has quick release too. The clear span is 100mm which may need to be tuned with a washer added to the right, geared side of the hub between the conical nut and the ribbed face nut during the assembly of the hub axis. • Equal size of wire attachment disc, otherwise you will need to purchase different length of wires too. Given that you already have a compatible bicycle, you can start ordering the drive components: • Motor. Do pay special attention to the choice of this component. Due to the out-of-ordinary nature of this project only the use of model outrunners will be described herein. No hub motors will be discussed as this competes with them both by price and by performance. I have found out that the smallest motor that suffices for a good ride is the AXI 4130/20 (a cheap replacement is a Turnigy TR 50-65-C, pay attention to the different shaft diameter), however, if you want a real joyride or if you plan to drive in the hills, you will prefer the Turnigy TR 63-54-A, or the extreme Turnigy C63-74. Unfortunately, one cannot rely on Turnigy's statements about permissible loads, so consider the maximum current being 1A per each 10g of motor mass. Supply the AXI with up to 76% of the maximum current stated as a burst 60s current. • Rear threaded hub or planetary hub gearbox (this does not require the freewheel). • Freewheel 18T meant for obsolete bikes with single gear ratio. Its inner threading fits the hub and the outer cylindrical part's diameter of 59.3mm fits the large gear wheel as described in the drawing below. • Bespoke gears or pulleys. My drawings are for a version without the gearbox nor the belt so that you may need to design your own. The pinion has a 6mm, H7 hole fit stated on the drawing, but you may change that to 8H7 or 10H7 for the Turnigy. Furthermore it is needed to adjust the number of teeth for these motors as described further below. • Battery. Find a cheap dealer of Lithium-polymer batteries. I bought these, but should you need a different number of cells than 3 or 6, try to buy the cells of type CSL6844127D or similar directly from a Chinese manufacturer BYD. Fill the designated space in the frame or the back carrying case with as many cells as possible. I ended up with 4S10P, 16V, 32Ah. • Brushless model speed controller (ESC). I have used a 85A version of the Mystery Blue line, but it seems that these have problems starting with batteries having more than 3 or 4 cells. • Plugs and cables. Take care about sufficient crosssection. I used 4×1,5mm2 of copper (that's 4×16AWG or 2×12AWG or even not recommended 1×10AWG) and 2 fastons for each pole. (You need another set of heavy wires for the other pole, I recommend buying a red and a black group.) Conductive loss is around 3%. • Charger. I am using the Xtrema product, but its firmware is not perfect and it's rather expensive for what it does. It however still supplies the highest current on the market: 8A. Never attempt to charge lithium batteries with car battery chargers! • Servotester. Choose the cheapest model controlled by a potentiometer only. This circuit accepts the voltage from the potentiometer in the range between 0 and 5V and produces a pulse-width modulated signal that controls the controller's throttle. It is needed to modify this circuit - solder away the pot, connect your own and, most importantly, connect the current limiter. This one has proven to be necessary after numerous tests. |

Ride | ||||||||||||||||

The bike is fully equipped and you can take on the road. The weakest motor mentioned goes about 32km/h (20mph), the fastest one promises up to 45km/h (28mph)! The gears are designed for operation on table land. During the driveaway up to 15km/h or uphill the overcurrent protection will kick in and you must help by pedalling or pushing shift down. If you are about to ride this in a mountain area, you should decrease the pinion teeth count by one third, that is 10 teeth with the strongest motor. It is not possible to get a lower number due to bad geometry of teeth.

|

||||||||||||||||

Gallery | |

View at the bike  Gear detail  Outrunner comparison |

© ZWZ, 2011.  Some rights reserved.

Some rights reserved.

Some rights reserved.

Some rights reserved.